Australian engineering tests show an average 14% improvement in braking distance, and up to 21% when fitted together with rear disc conversion kit. Features Include

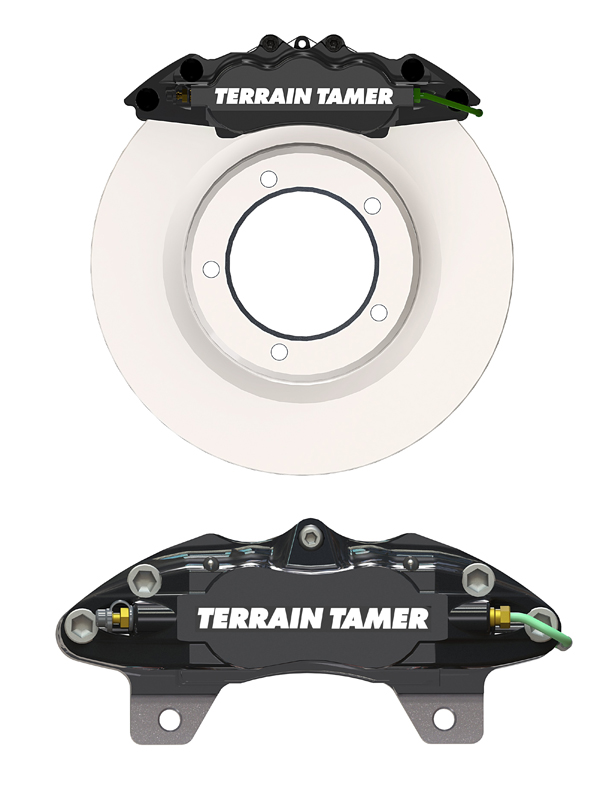

Improve your braking performance with Terrain Tamers Big Brake Kit

Braking distance plays a crucial role in road safety, and advancements in automotive engineering continue to enhance this vital aspect of vehicle performance. Recent tests of Terrain Tamer’s Big Brake Kit conducted in Australia have shown promising results, revealing an average 14% improvement in braking distance. Moreover, when combined with a rear disc conversion kit, the improvement can be as high as 21%. We will delve into the details of these tests, explore the key features of the braking system, and discuss the necessary engineering and safety standards for installation.

As drivers, we understand the significance of responsive and efficient braking systems. They provide us with the confidence to navigate the roads safely and effectively. Manufacturers and engineers are constantly working to improve braking performance, and the results of the Australian engineering tests demonstrate notable progress in this field.

The Importance of Braking Performance

The performance of brakes plays a crucial role in ensuring safety and control while navigating off-road terrains. The ability to achieve a shorter braking distance can be the decisive factor between narrowly escaping a potential accident and experiencing a collision in challenging terrain in your 4wd. It empowers drivers to swiftly respond to unforeseen obstacles or abrupt alterations in terrain conditions. Terrain Tamer has developed a brake kit suited for Australian conditions.

Big Brake Upgrade Kit: Australian Engineering Tests and Results

The Australian engineering tests were conducted to evaluate the braking performance of the big brake upgrade kit. The results were impressive, revealing an average 14% improvement in braking distance. This improvement can be attributed to various factors, including the design and features of the braking components.

Up to 21% Improvement with Rear Disc Conversion Kit

The braking kit system's performance was further enhanced when paired with a rear disc conversion kit. The combination resulted in an impressive improvement of up to 21% in braking distance. This upgrade provides even greater stopping power and allows for increased control over the vehicle in various driving conditions.

Key Features of the Big Brake Upgrade Kit Braking System

The improved braking performance can be attributed to several key features of the braking kit. These features work in harmony to deliver exceptional stopping power and responsiveness. Let's explore them in more detail:

Enlarged 2 Piece Forged Aluminium Calipers

The braking kit utilises enlarged 2 piece forged aluminium callipers. This design ensures greater strength and durability while minimising weight. The lightweight construction helps reduce unsprung weight, which positively affects the overall handling and performance of the vehicle.

6 Pot (Front) or 4 Pot (Rear) Calipers

The braking kit comes with a pair of 6 pot callipers for the front wheels or 4 pot callipers for the rear wheels. These high-performance callipers provide consistent and even clamping force on the brake rotors, resulting in improved braking efficiency. The callipers are engineered to withstand high temperatures and maintain optimal performance even during demanding driving conditions.

Increased Swept Area with Geomet-Coated Rotors

This 4WD braking kit incorporates 6-slot or 10-slot and dimpled Geomet-coated rotors, which offer up to a 40% increase in swept area compared to OE rotors. The larger surface area improves heat dissipation and enhances braking performance, especially during prolonged or heavy braking. The Geomet coating provides corrosion resistance, prolonging the lifespan of the rotors.

Matching Caliper Brackets and Bolts

To ensure proper installation and optimal performance, the braking system includes matching calliper brackets and bolts. These components are engineered to fit seamlessly with the callipers and other braking system elements. The precise fit and compatibility enhance the system's overall integrity and functionality.

Kevlar Ceramic Low Dust Brake Pads

The brake pads in the system are made from kevlar ceramic material. These pads offer excellent friction characteristics, resulting in responsive and efficient braking. Additionally, they produce less brake dust compared to traditional brake pads, reducing maintenance and keeping the wheels cleaner.

Stainless Steel Braided Hoses

The braking system includes a full axle set of stainless steel braided hoses. These hoses provide enhanced durability and improved brake pedal feel. They are resistant to expansion under pressure, ensuring consistent brake performance and a firm pedal response.

High Grade Alloy Steel Brake Pad Insulators

The brake pad insulators are made from high-grade alloy steel, ensuring efficient heat transfer and minimising heat-related brake fade. The insulators help maintain consistent braking performance and prevent premature wear of the brake pads.

Stainless Steel Abutments

The braking system incorporates stainless steel abutments, which serve as guides and supports for the brake pads. These abutments ensure proper alignment and movement of the brake pads, contributing to consistent and even braking performance.

Engineering and Safety Standards of Terrain Tamer Brake Upgrade Kits

It is essential to highlight that the big brake upgrade kits are fully engineered and ADR approved. This means that they have undergone rigorous testing and meet the necessary safety and performance standards set by the Australian Design Rules (ADR).

Installation by Qualified Mechanics

To ensure proper installation and functionality, these braking system kits should only be installed by qualified mechanics. The installation process requires technical expertise and precision to guarantee optimal performance and safety.

Engineer Inspection and Compliance with State Regulations

After the installation of the braking system upgrade kit, it is crucial to have it inspected and signed off by an engineer. This step ensures compliance with state regulations and validates the safety and effectiveness of the upgraded braking system. It is imperative to follow these procedures to meet the necessary legal requirements and maintain the overall safety of the vehicle.

Choose the Terrain Tamer Big Brake Kit for your 4WD

The Australian engineering tests have demonstrated a remarkable improvement in braking distance, showcasing the potential for enhanced safety and performance on the roads. The Terrain Tamer braking system offers various features that contribute to this improvement, including enlarged forged aluminium callipers, Geomet-coated rotors, and high-performance brake pads. It is crucial to follow the recommended engineering and safety standards during installation and ensure compliance with state regulations.

By choosing a braking system that has undergone extensive testing and meets industry standards, drivers can enjoy increased peace of mind, knowing they have invested in their safety and the safety of others on the road.

Frequently Asked Questions About Brake Upgrade Kits

What is a big brake upgrade kit?

A big brake upgrade kit is an aftermarket component that replaces your vehicle's existing brake system with a more performance-oriented kit. It usually includes upgraded rotors, callipers and pads, as well as other parts such as lines and brackets. The purpose of this upgrade is to provide improved braking power, better control in emergency situations, and improved longevity.

How does big brake upgrade work?

A big brake upgrade kit replaces your vehicle's existing braking components with larger, more powerful ones. The upgrade includes new rotors and callipers that allow for a greater amount of heat dissipation and stopping power. In addition, improved pads, lines, and brackets are included to ensure that everything is properly connected and functioning properly.

What are the advantages of a big brake upgrade?

The primary advantages of a big brake upgrade kit are improved braking performance and greater durability. The larger rotors allow for better heat dissipation, meaning less fade and more consistent stopping power. In addition, the callipers provide more clamping force on the pads, providing better control in emergency situations. Finally, the upgraded lines help to ensure that your vehicle will be in your control.

Are these braking upgrade kits suitable for all types of vehicles?

These braking system kits are designed to fit specific vehicle models. It is essential to check compatibility before purchasing and installing the kit. It is recommended to consult with a qualified mechanic or the manufacturer to ensure the proper fitment for your vehicle.

Will the installation of a brake upgrade kit void my vehicle's warranty?

While the installation of aftermarket braking system kits may not void your entire vehicle warranty, it can potentially affect the warranty coverage for braking components. It is advisable to consult your vehicle manufacturer or warranty provider to understand the specific terms and conditions regarding modifications.

How often do the brake pads need to be replaced?

The lifespan of brake pads varies depending on several factors, such as driving style, road conditions, and the type of brake pads used. Generally, brake pads should be inspected regularly and replaced when they reach a certain wear limit specified by the manufacturer. It is recommended to follow the maintenance schedule provided by the braking system manufacturer or consult with a qualified mechanic.

Can I install these kits myself, or do I need a mechanic?

The installation of these braking system kits requires technical expertise and precision. It is recommended to have them installed by a qualified mechanic who has experience working with braking systems. This ensures proper installation, functionality, and compliance with safety standards.

Video Transcript:

https://www.youtube.com/watch?v=iPur6dYeye0

Installing Big Brake Upgrade Kits: A Step-by-Step Guide

Terrain Tamer strongly recommends entrusting all brake-related tasks to a certified mechanic.

- Elevate the vehicle using a hoist and remove the wheels. Securely clamp off the flexible brake hoses to prevent fluid leakage.

- Loosen the brake pipe and eliminate the retainer clip and pipe retainer bracket.

- Unbolt the calliper bolts and discard both the calliper and disc rotor.

- Make space for the larger rotor by removing the back plate. Thoroughly clean the rotor mounting face. To ensure proper clearance, temporarily fit the new disc rotor using two wheel nuts and check the back plate.

- Attach the spacer bracket and calliper to the housing, ensuring that the rotor is centrally positioned between the calliper sides.

- Apply an anti-scrawl compound to the disc pad breaking plate, then proceed to install the pads.

- Install the anti-rattle springs and secure them with bolts.

- Install the new flexible brake hose.

- Reinstall the retainer spring clip and hose retainer bracket, ensuring proper alignment with the hose.

- After reattaching the wheels, allow the brakes to settle by driving the vehicle and gradually applying the brakes to bed in the new brake pads. Close